Throughout 2021, contractors across the country have been facing an ongoing (and even escalating) problem: Building material prices are increasing sharply.

Yield PRO, citing data from the U.S. Bureau of Labor Statistics, notes just how drastic these price increases have been:

- The cost of sheet metal has increased 21.2% since June 2020 — and 8.1% from May to June 2021

- Softwood lumber has seen a 125.3% year-over-year increase

- Soft plywood’s cost has exploded by 207.1% since last year — and is up over 20% since May 2021

As the Federal Reserve Bank of Minneapolis explains, causes for the building materials price increase vary. Surprisingly, the global shutdown isn’t necessarily to blame — and in many cases wasn’t a factor at all. (It’s worth noting that the other points mentioned — increase in demand, increase in tariffs, weather-related stoppages, and more — will likely continue to factor into material pricing in the future. In other words, the issue of pricing might not be going away for a while.)

Unfortunately, the building materials price increase is leaving many contractors with seemingly very few options.

With little idea of when building material prices will go down, though, something must be done to keep things moving.

In some cases, contractors and subcontractors are simply eating the increased construction costs. This is especially true for those who had signed onto projects before prices began spiking.

New Projects and Potential Issues

When taking on new projects, many contractors have begun factoring the increased price of construction materials into their contracts as usual.

There are 2 potential problems here:

1. For one, the price could easily increase in due time — leaving contractors in the same boat as the above.

2. Worse yet, teams that raise their prices too high can end up missing out on contracts altogether.

In any case, it isn’t exactly an ideal situation for contractors (or their clients).

Still, there are a number of ways to manage the problem and minimize the damage it causes your construction business.

Let’s take a look at 6 key things contractors are doing to handle surging building material prices today.

1. Adjust the Price and Scope of Current Projects

As mentioned above, it’s common practice for contractors to adjust their pricing based on the fluctuating cost of materials. This typically doesn’t result in an all-too-drastic change in price for the building owner — at least in “normal” times.

But with the price of certain materials rising so quickly, taking this same approach can cause sticker shock for project owners, which may cause them to look elsewhere to get their project built.

(That said, if your clients are willing to pay the increased cost with minimal issue, you can consider the problem solved.)

For project owners, the other option is to change the scope of the project. As a contractor, you’ll need to work with your clients to identify ways to do so that will keep material costs down while allowing the owner to get what they need from the new build.

2. Add Price Escalation Clauses to Contracts

The price volatility has made it essential for contractors to include price escalation clauses into their client contracts.

These clauses allow contractors to renegotiate a project’s overall price should the cost of materials increase substantially from the time a contract is signed to the moment they break ground.

The most common approaches to these clauses are:

- Index Method: Using an objective measure, such as the Turner Building Cost Index, to dictate changes in project price

- Invoice Method: Identifies specific building materials that are subject to price volatility that can trigger contract renegotiations

- Threshold Method: Defining a percentage point cost increase that will trigger renegotiations or a predefined project price increase

3. Fix Costs by Preordering Materials

Many contractors are working under the assumption that certain building material prices are going to keep climbing for the foreseeable future.

That being the case, many construction companies have begun ordering certain materials almost immediately after signing onto a new project — even if they won’t be breaking ground for some time.

Contractors going this route will have a couple things to consider.

First, there’s the cost of storing and maintaining the materials over time. If these costs outweigh the cost of simply buying the materials in the future, there’s no reason to do so.

Second, there’s the chance that material prices will drop before the project commences. In this case, the contractor would end up eating the additional cost — and watching it cut into their profit margin.

So, the best course of action may be to preorder materials that are all but guaranteed to continue increasing in price as well as can be stored and maintained in a cost-effective manner.

4. Use Alternative Materials

Some project owners and contractors have skirted the issue of rising material prices by using alternative materials altogether.

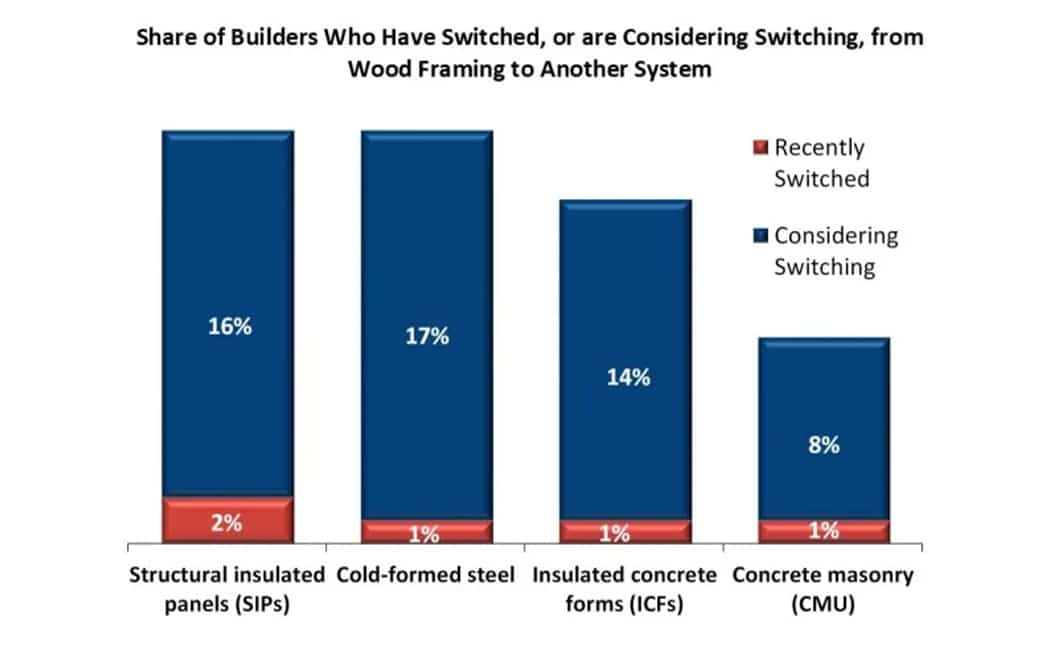

Alternatives to lumber, for example, continue to grow in popularity.

While a small percentage of contractors have actually switched to these alternatives, many more are considering it should lumber prices stay on the rise.

Contractors thinking of switching to alternative building materials will need to communicate the benefits of doing so to their clients. More than just explaining the upfront savings, contractors can focus on material quality, durability, and other such features to ensure the client is on board with the change.

Focus on Pre-Construction Engagement

In such an uncertain environment, contractors and their clients need to be more aligned than ever before.

In short, an intensive pre-construction process has become essential.

During the pre-construction phase, contractors and project owners will collaborate to:

- Define, communicate, and understand the goals of the project

- Develop a comprehensive and cohesive plan of attack

- Anticipate any roadblocks that may be encountered

- Define the scope of the project, and each party’s responsibilities

For our purposes, this ensures both parties come to a mutually beneficial agreement regarding building material pricing. Zooming out a bit, a more intensive and collaborative pre-construction period will lead to a better overall experience for both the contractor and their client.

5. Invest in Emerging Tools and Technology

For contractors, there are a number of emerging tools and software available to help combat the building materials price increase.

To be sure, there are many tools that can enable construction teams to accomplish a number of the things we’ve touched upon.

Here are a few examples:

- Project estimation tools can help contractors nail down optimal material pricing to use as a baseline when sourcing for future projects.

- Communications tools can allow contractors and clients to stay in close contact throughout pre-construction and construction — and to keep each other apprised of any changes to be made to the project scope or price.

- Design and construction tools allow contractors to develop an optimized and cost-effective plan — and to communicate this plan to their client in a way that makes sense to them.

Emerging technology will continue to play a critical role in today’s uncertain and volatile construction market.

For contractors, it’s vital to know how to use these tools to get the most accurate and dependable guidance possible. While there’s no way to completely avoid being impacted by market volatility, you’ll at least be equipped to keep things moving in the right direction for both your team and your clients.